Using Breadboards

If you're into electronics, you probably

know - and use - breadboards. But if

you're new to the game, these handy

devices will make it a lot simpler!

Here's a brief introduction.

Using Breadboards

These imentation, onto PCBs, days, 99% or circuit Printed of electronics development Circuit Boards. projects and "proof But arefor soldered of exper- concept" (ie, does it work!), nothing beats a solder-less breadboard (sometimes called a prototyping board).

Every hobbyist and even professionals should have one or more of these in their arsenal! They're available in various sizes, depending on your particular applications.

However, it may be that you have never used one of these before so a few words of explanation now might save a few tears later!

What are they?

They're simply a way of mounting and connecting components, thus making it easier to work out what you're doing and at the same time, minimise the chances of components or connecting leads shorting to each other (with possible catastrophic results!).

The one thing they all have in common is rows and columns of holes, into which you can poke component leads. Depending on which holes you choose/use, they may connect to other components. The rest will require connecting leads, also known as jumpers leads (no, not the ones you use to get a car started!).

Some breadboards are supplied "as is"; others may have additional circuitry alongside to mate with a particular platform (such as Arduino).

Size

Breadboards are available in a range ofsizes from the mini (about 40mm x 87mm and with 17 x 10 holes for a total of 170) right through to 157 x 273mm monsters with 2309 holes; some (like the photo shown opposite) are mounted on a backing plate which may have rubber feet plus provision for power, earth, etc via binding posts.

Some, like the mini type, are designed to clip into each other ifyou need a larger board. Others (especially the larger ones), are the opposite - they're designed to have their segments separated so the configuration can be changed.

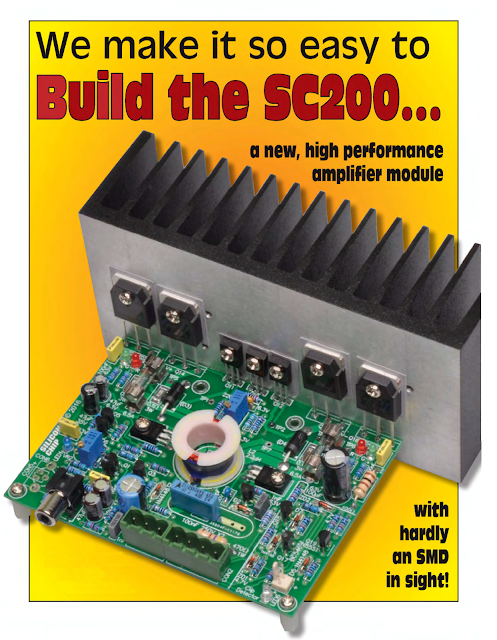

And there are also variations in the board design - most feature a very obvious gap (or more than one) across the siliconchip.com.au middle - suitable for mounting ICs etc. And it probably shouldn't surprise you to find that the spacing between the holes is 0.1 inch, the same as the pin spacing on ICs and many other components.

The holes

One thing that is universal to all breadboards is that under every hole is a pair of (usually) sprung brass connectors, so that any component or wire poked into that hole will connect to it.

Most "typical" wire component leads will fit into the breadboard holes; some larger components or components without wire leads will need to be connected by wires soldered to the component.

Hole identification

Another thing is almost universal: along all the edges are a series of numbers and letters, so you can identify a particular hole by reading the two values. These are often molded into the plastic which makes them rather difficult to see, but they are there if you look closely!

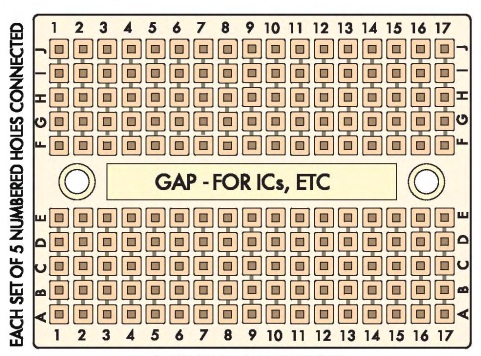

A typical mini breadboard (see top of page) showing the relationship between the holes. The connection between each of the five holes in each set is inside the breadboard. Larger breadboards follow a similar number/letter scheme but are often divisible to allow easier configuration of circuit elements. If you're buying a new breadboard, you'd be better off buying a larger one than a small one.

This kit of handy insulated jumper leads is specifically made for breadboard use. 70 pieces in various lengths and colours are supplied with ends bared and bent at 90°. It's available from Jaycar Electronics for $13.50 (Cat PB8850). Altronics have a similar, though larger kit (350 pieces) for $32.50 (Cat P-1018).

For example, on the mini board shown above hole C9 would be on the third row up from the bottom and right in the middle horizontally.

On larger boards, the numbers are usually printed and easier to see (see opposite).

Columns of numbered holes are connected

Invariably, there are many columns of five holes, "numbered" for identification. Each of these five holes are connected to each other. So any component lead (or connecting wire) placed in these holes will be connected to other holes in the same row.

Larger breadboards have multiple groups of five holes

But rows of lettered holes are not!

In most cases, rows of "lettered" holes (eg, ABCD, etc) are NOT connected together, so you can mount a multi-leg component and connect it with jumpers, as explained below.

Bus bars

The exception to this is where is a line is printed on the board adjacent to the holes, especially (but not always) along the edges of the board (see above right).

It's normally red (for+) and blue (for-) and is to allow one or more convenient supplies or earth lines. Because there are usually multiple connections to power and earth, it's more convenient to have these "bus bars" run right along the edges - and sometimes down the middle and on top, as the Altronics deluxe breadboard shows.

Connecting wires or "jumpers"

Connections between components are made with "jumpers". Where two close holes are to be connected, an appropriate length of component lead offcut is often used. However, this does not allow the jumpers to cross over each other unless at least one of the wires has insulation on it.

For longer cross-board connections, many breadboard kits are supplied with insulated jumpers for this purpose. If you run out, or if you don't have any with your breadboard, lengths of sturdy, insulated, single copper or tinned copper wire are used. This is sometimes known as bell wire - or can be cut from older 4-wire (single strand) cables of the type used for phone or alarm wiring.

Once the four colour-coded wires are stripped from the outer sheath, they're each cut to appropriate lengths and about 5-10mm of insulation is removed from each end.

Note that multi-strand wire is not very successful because

the strands tend to bend and separate as they're pushed into the holes. If you must use a multi-strand wire, lightly tinning the ends may help.

complete with four terminals. Note the numbered columns and lettered rows plus the ten supply rail rows, marked by red and blue lines. Available from Altronics

Low voltage only!

Note that breadboards can only be used with low-voltage circuits (say up to about 50V). Over this voltage they really aren't safe when there is so much exposed component wiring about. Maximum current would be 200mA or so.

And now for today's trivia!

Why are they called breadboards?

Way back in the "olden days", decades before the luxury of prototyping boards, experimenters used to assemble circuits with point-to-point wiring. The problem was, the components moved about, so they need a firm base onto which they could fasten things like valve holders; something they could screw into.

For this, a relatively large piece of softwood was the go ... and where was the ideal candidate?

Of course! In the kitchen-Mum's breadboard! (But only if you could get away with it).

Much, much later a very clever bloke named Dick Smith used a very similar approach for the original "Fun Way into Electronics" projects. Except he advised constructors not to pinch mum's breadboard but use small scraps of timber instead!

Comments

Post a Comment